Nehmen Sie einfach Kontakt mit uns auf. Sie können uns werktags zwischen 08:30 und 17:00 Uhr erreichen.

How to set up a compressor control with a MH300 frequency inverter

Energy savings from a refrigeration compressor

By connecting a frequency inverter to a refrigeration compressor, you can adjust the cooling capacity according to the system's cooling demand. This can result in significant energy savings. By varying the compressor speed based on the cooling demand, stable system pressure is created. This also reduces maintenance costs.

Because a frequency controller can be used to control the compressor speed higher than the mains frequency, in many cases the compressor cooling capacity can be increased by approx. 20 %.

Basic connections

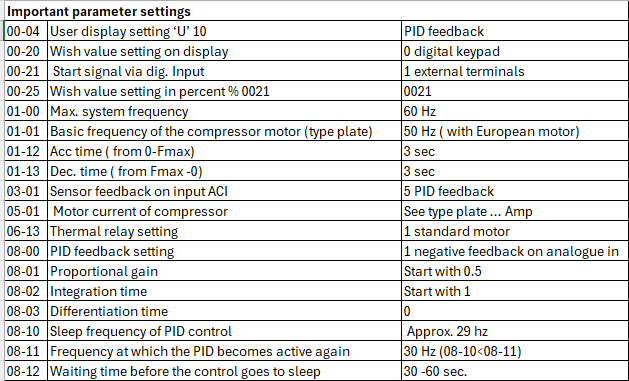

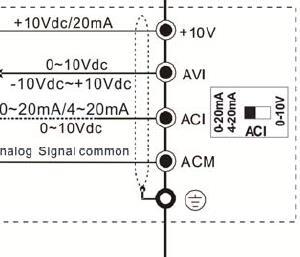

Below are some important settings to enable Compressor control based on pressure. It is important which pressure sensor is used; 0-10volt or 4-20mA and two-wire or three-wire. Most common is 4-20mA in a two-wire version.

1. Connect power supply of the sensor to +10V and the signal side to the ACI.

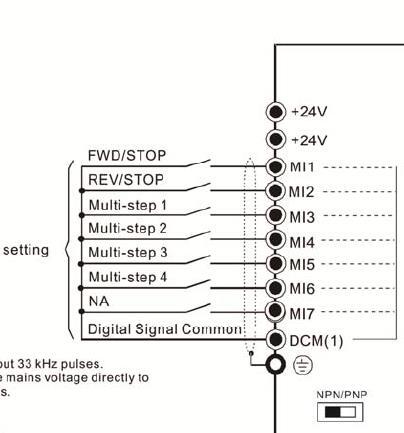

2. Create a start signal between the DCM and Mi1.

3 Settings

To pressurise a system, you need to enter a wish value indicating the system to be controlled. The actual system pressure is then fed back via the pressure sensor, with which the frequency controller will then try to adjust the compressor speed to bring this pressure into line with the wish value. The most commonly used method is to set the wish value on the drive's display. As the MH300 does not have a text display, you can only work in Hz or % here. With a pressure control, it is convenient to work in %. Set 00-25 to 0021 The value F in the display then becomes % of 0-100.0.

You can then set the desired pressure between 0-100.0 percent( is 0- max. sensor pressure).

To get the sensor value in the PID you have to set parameter 03-01 to 5( PID feedback)

To monitor this value it is useful to set 00-04 to 10( PID feedback monitor)in The User defined display ‘U’ you can then monitor the sensor value.

Furthermore, the PID operation must be activated.(08-00) For a compressor, you want the speed to increase if the feedback value is lower than the setpoint ( negative feedback) and the value comes in via the analogue input so setting 1

Furthermore, it is important for the system that the control will run stably in case of deviation in the sensor value. For this, 08-01 (Gain) 08-02 (Integration time) and possibly 08-03( Differentiation time) must be set to the system's response. This depends entirely on the system and the power of the compressor.