Nehmen Sie einfach Kontakt mit uns auf. Sie können uns werktags zwischen 08:30 und 17:00 Uhr erreichen.

How do I set up a PID control?

Description how to set up the Delta C2000 for pressure feedback with a 0-20 mA sensor. 0-40 Bar.

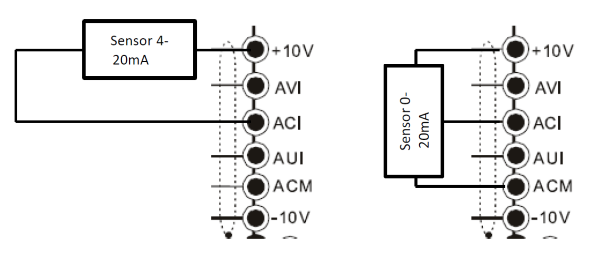

1. Sensor connections

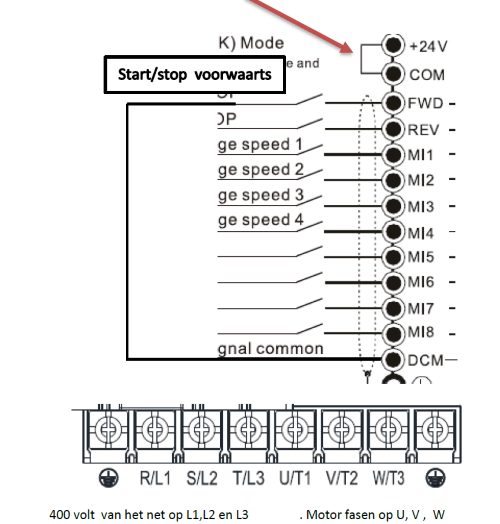

2. Connecting start/stop signal to FWD and DCM . bridge from +24 V to Com.

Parameter setting :

00-00 9 reset to 50 Hz.

00-04 12 diplay the value of the ACI input

00-21 1 start/stop via terminals

00-25 0161 reading in BAR 1 decimal place

00-26 0400 maximum setting is 40.0 Bar.

01-12 at will acceleration time approx. 3 - 5 sec.

01-13 discretionary deceleration time approx. 3-5 sec.

03-00 0 AVI no function

03-01 5 ACI is PID feedback

05-01 motor current type plate

06-27 1 thermal protection switched on for standard motor

08-00 1 PID negative feedback on analogue input

08-01 at will proportional gain higher is faster reaction in case of deviation

08-02 at will integration time damping for feedback higher is longer damping time.

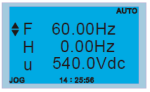

Apply power to the controller and look at the display first . In the display for F you should see a value in Bar or a value in %. If it says 0 and the sensor has pressure, it is probably connected the wrong way round. If this value goes along with the pressure on the sensor, we know that the sensor is connected correctly.

Now set :

00-04 10 diplay the value of PID feedback coupling.

You should now see at the readout U again a value however between 0-40 Bar.

If that is correct then the PID feedback is also working. Now run the pump and see if the control responds properly otherwise adjust 08-01 and 08-02.