Nehmen Sie einfach Kontakt mit uns auf. Sie können uns werktags zwischen 08:30 und 17:00 Uhr erreichen.

How to apply the 87Hz principle to an inverter?

What is the 87Hz principle and when do you apply it ?

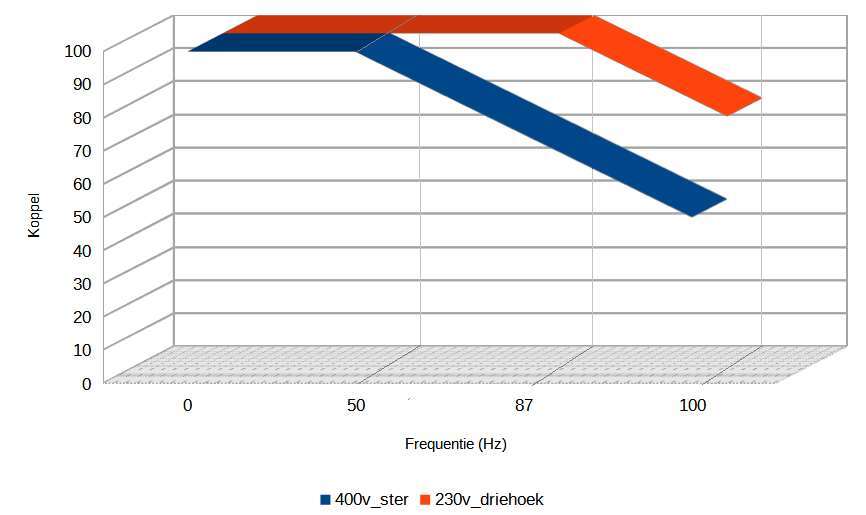

The 87Hz principle (also called the √3 principle) can be applied to maintain torque at a frequency higher than the motor's base frequency.

A standard AC motor 50Hz/400V (connected in star) delivers its rated torque up to 50Hz. At frequencies above 50Hz, torque decreases.

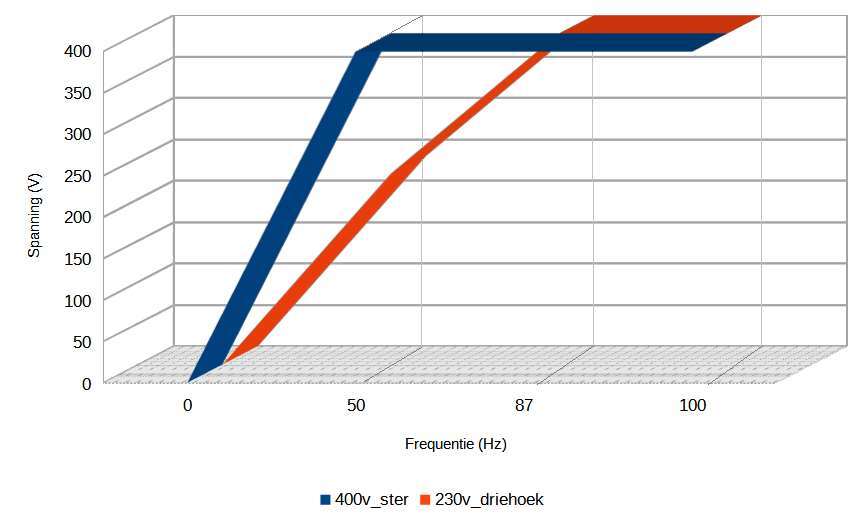

Up to a frequency of 50Hz, frequency and voltage are controlled, from 50Hz onwards, only frequency is increased and voltage remains 400V.

If a voltage of 400V is output at 50Hz, then at 25Hz the output voltage is 200V. The ratio of voltage to frequency is then constant (400/50 = 8V/Hz and 200/25 = 8V/Hz).

If the frequency is increased further to e.g. 80Hz, then, since the voltage is not increased further, this ratio becomes 400/80 = 5V/Hz.

This causes the motor to go into the so-called field weakening mode and the torque decreases inversely with speed. For example, when the speed doubles (100Hz), the torque is half.

In many cases, the lower torque is not such a problem, but sometimes it is important to maintain nominal torque at frequencies above 50Hz. In such cases, you can apply the √3 principle.

What are the conditions for applying this principle ?

In order to use a motor and frequency converter in this way, there are some conditions:

- The motor must be wound for 230V_delta/400V_star and be suitable for 87Hz.

- The motor (and the implement connected to it) must be mechanically suitable for the higher speeds. (Almost always a 4-pole-1500 rpm motor is used for this purpose).

- Operation above 50 Hz is for shorter periods.

- Because of additional losses in the motor, the thermal load is higher. We recommend monitoring the motor for temperature, e.g. with PTCs. Depending on the application, in certain cases it may be better to choose the motor one or two steps larger.

- The AC drive should be suitable for the current at triangular connection of the motor. For example, for a 2.2kW motor, the inverter must become √3 x 2.2kW = 3.81kW = 4kW.

How do you connect the motor ?

By connecting the motor in triangle and setting the inverter differently, the frequency can be increased to 87Hz while still delivering almost the rated torque.

The larger control range gives the machine or implement more flexibility. A 4-pole motor with a nominal speed of e.g. 1440 rpm at 50 Hz, then turns 2505 rpm at 87 Hz.

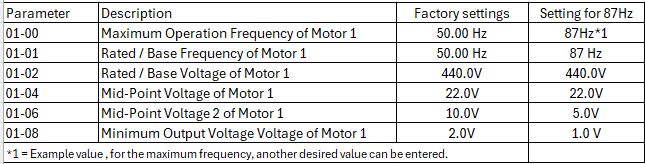

How is the frequency inverter set?

The frequency converter is set so that the voltage-frequency ratio remains constant up to a frequency of 87 Hz.

To do this, the base frequency of the inverter is set to 87Hz. This means that the voltage of 400V is reached at 87Hz. It follows that at a frequency of 50Hz, the voltage is 230V.

With this technique, frequency and voltage are controlled over the entire range 0 - 87Hz. The ratio of voltage to frequency is constant over this entire range and so the torque also remains constant up to 87Hz.

Parameters to be set:

This principle is usually applied to 50Hz motors, for 60Hz motors this √3 principle can also be used. Then the base frequency is set to 60 x √3 =104Hz.